How is Field Service Inventory Planned?

Field Service Technicians introduce challenges that common multi-echelon planning algorithms used for Central Warehouses and Forward Stocking Locations do not address. Technicians frequently determine their own inventory needs based on undocumented knowledge and experience that can’t be used to scale as your service supply chain evolves. This gap in process, data and technology represents an untapped opportunity in many service organizations to improve service supply chain performance and improve first call fix rates.

How Big is This Opportunity?

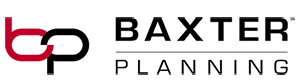

A technician’s time is a valuable resource and making a technician more productive by reducing the need for return visits due to lack of parts is an incredible opportunity for return on investment. Consider the following example:

Find out for yourself how Baxter can optimize your service supply chain inventory.

Complete this form and we’ll get in contact with you or email us at info@baxterplanning.com / call us at +1 (512) 323 5959 .

This example is based on a 10% reduction in broken calls due to lack of part availability. This results in 25,000 fewer broken calls requiring return visits per year. If each return visit takes an additional 2.5 hours of technician time (part ordering, return trip drive time, and additional on-site work time), that’s $3.1M in gained technician productivity annually. That’s also a big reduction in dissatisfied customers.

One of the best investments a field service organization can make to improve their part availability and improve the productivity of their technicians is to reduce the need for return visits. Prophet by Baxter is the industry leading solution for field service inventory planning.

What Makes Field Service Inventory Planning Different?

Networks of physical warehouses are relatively static, both in position and the overall number of locations. Technician workforces are more dynamic. Technicians are mobile and change product responsibility. Technician territory assignments can also change frequently to maintain workload balance. These attributes create a unique set of problems.

- Turnover: It’s not unusual for a technician workforce to have 10% turnover in a year. If the overall organization size stays stable, that’s a loss of 100 trained technicians a year in a workforce of 1,000. Newly added technicians don’t necessarily service the same population of customers and products as the technician they replace, so field service managers regularly shuffle technician territories and assignments to match their workforce and customer base.

- Incomplete or Incorrect Demand History: Technician inventory can’t be efficiently planned using only each technician’s individual “demand history.” Demand history based inventory planning will always be reactive; as there is no plan until that individual technician has experienced demand. When demand occurs before there’s a plan, broken service calls and return visits are the inevitable result. A combination of incorporating installed base knowledge and team/territory assignment knowledge into the plan is critical for success.

- Training: Technician training requirements change over time. As new products are introduced, a limited subset of technicians may be trained to service those products. Understanding which technicians are candidates for parts based on training and call assignment rules is critical.

- Plan Stability and Excess Avoidance: Technicians are people, not buildings, and have limited inventory storage space. Technicians will notice an unstable inventory plan that adds, removes, and re-adds the same part within a short period because they must book those transactions themselves. Plan instability costs money in transportation expense and lost technician productivity, and erodes confidence that a centrally managed plan is doing a better job than they could do on their own. After a time, technicians will demand overrides or simply stockpile additional parts, creating excess and reducing the effectiveness of an inventory optimization strategy.

What is the Solution?

At Baxter Planning Systems, we don’t apply a one-size-fits-all planning model to technicians. Field service inventory planning needs to move beyond traditional multi-echelon inventory optimization models. The combination of Baxter’s industry-leading cost-optimization inventory planning algorithms AND unique features specifically developed to support the planning of field service inventory make Prophet by Baxter the most specialized and successful solution for planning technician inventory available.

- Cost-Optimization: Baxter’s unique cost-optimization algorithm understands the costs associated with not stocking a part to determine the optimal stock levels.

- Technician Teams and Territories: Baxter’s planning logic understands technician and installed base team/territory assignments. Our algorithms understand that multiple technicians may be candidates to service a specific customer or piece of equipment in the future, even if a specific technician hasn’t serviced that customer or product recently.

- Technician Training and Proficiency: Baxter considers each technician’s training and proficiency on individual products and the likelihood of taking specific service calls when planning for technician inventory.

- CRM or Route Optimization (RO) Call Assignment Rules: Baxter accounts for call assignment rules in your CRM or RO software and blends territory assignments, training, current technician inventory, and recent technician history when determining future call assignment expectations and required inventory to support those service calls.

- Inventory Plan Stability: Baxter applies multiple factors to maintain plan stability when the cost of change outweighs the projected benefit of change. This limits plan instability, avoiding excess movements and loss of technician confidence in the planning solution.

- Multi-Echelon Inventory Optimization: Baxter’s unique cost-optimization and multi-echelon optimization algorithms stock parts at the most total cost-justified (inventory, productivity, transportation mode) echelon of inventory, and consider technician stocking when recommending stock levels at higher echelon locations such as 3PL regional distribution centers and local forward stocking locations (FSLs).

- Continuous Improvement: Baxter’s unique Planning Analytics determines root causes for broken calls due to part availability, allowing planners to address execution and data quality issues to improve service level. Even with a worldclass planning solution, there will be broken service calls. The key to continuous improvement is to identify, categorize, and resolve issues that cause broken service calls.